Beautiful Basements was appointed as the specialist designer and builder for the basement for the new build of a very large house in rural Nottinghamshire.

The basement was to built from reinforced concrete (RC) walls and slab to create the foundations for the house above. The client’s main contractor carried out the excavation and the blinding of the formation level. Beautiful Basements then created the slab, fitted the three pumping stations, built the shuttering for the walls, installed the steel work and cast the RC basement walls.

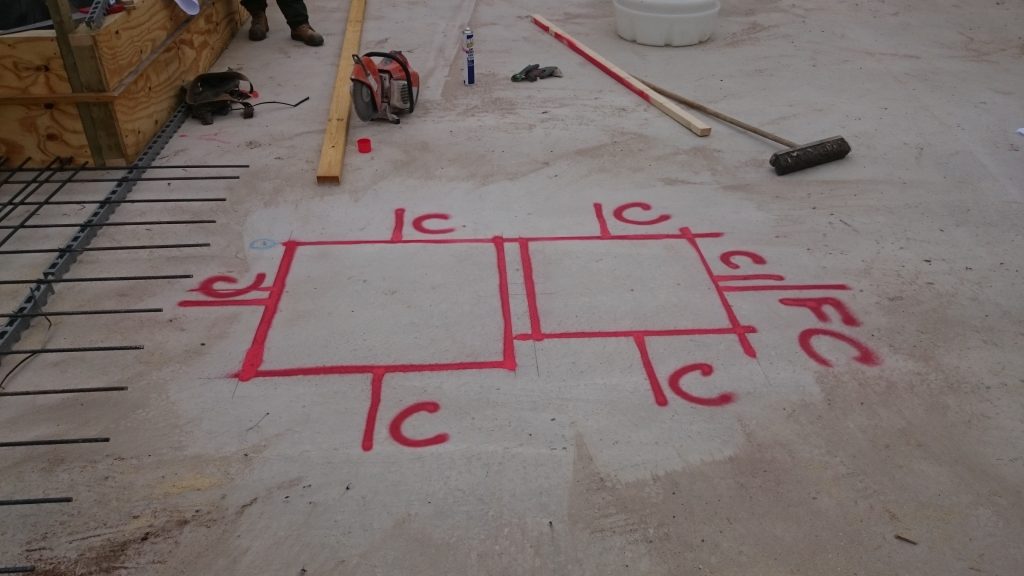

Type C – Internal Cavity Drainage System

Internally the main floor slab was cast to fall, meaning gravity would divert any water to one of the two groundwater sump stations.

The walls and floor were lined with a cavity drainage membrane (CDM)

Two pumps and one high level alarm were fitted to each of the sump stations

Membranes & sumps were supplied by Triton Systems.

Externally the walls, kicker and slab toe were treated with a waterproofing slurry to slow any water ingress.

External slurries were supplied by Koster Aquatecnic.