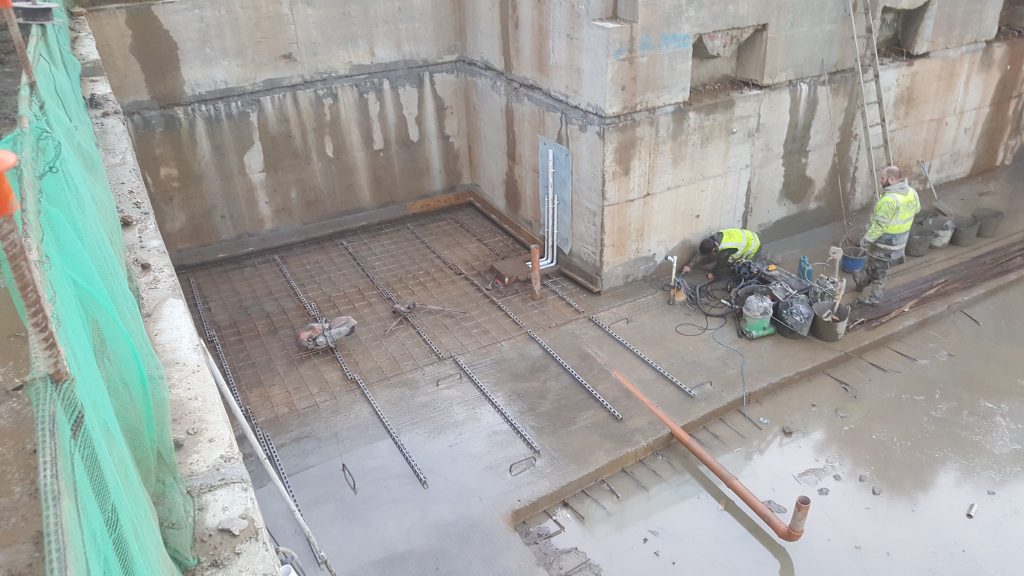

Beautiful Basements was awarded the contract to build a new basement using a ring beam & underpin methodology.

On a very confined site, temporary works as part of permanent retaining walls was required to prevent damage to neighbouring properties. The outline of the basement is less than a meter from both neighbouring properties.

The ring beam & underpin method ensured the excavation never collapsed on the crew and causing damage to the neighbouring properties.